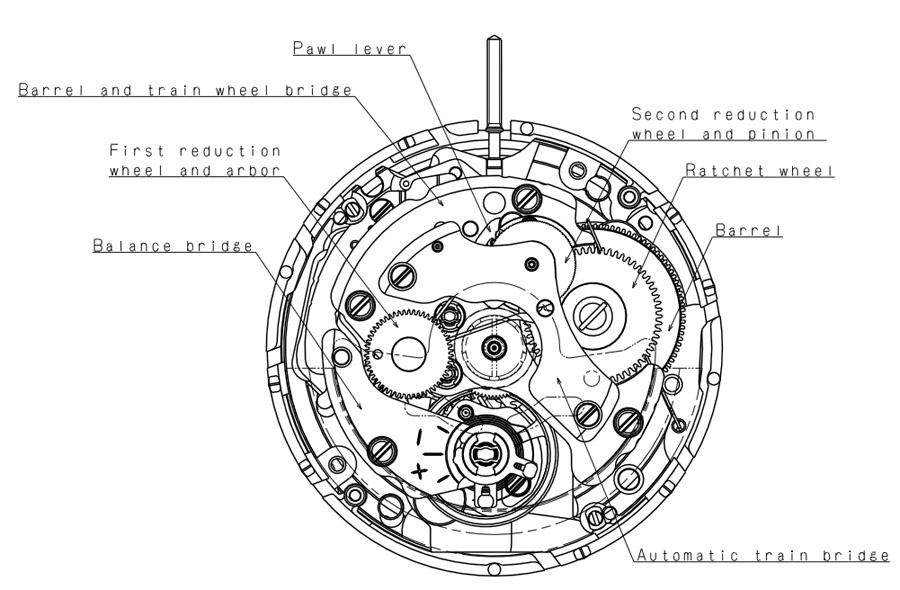

Common Issues and Solutions: Troubleshooting Your NH35

While the NH35 is renowned for reliability, understanding common issues and their solutions helps owners maintain optimal performance and recognize when professional service is needed.

Accuracy and Timekeeping Issues

Gradual Accuracy Drift

Many NH35 owners notice their watch gradually gaining or losing time over weeks or months, even if it initially kept excellent time.

Causes: Natural lubricant aging, mainspring fatigue, positional component wear, or magnetization from daily life exposure.

Solutions: Magnetization can often be resolved with demagnetization by a watchmaker ($20-40). Gradual drift usually requires regulation ($75-150) or, in extreme cases, full service. If the watch is relatively new (under 2 years) and experiences sudden accuracy changes, consider warranty service.

Sudden Accuracy Changes

Abrupt timing shifts of 30+ seconds per day often indicate specific problems rather than normal aging.

Primary Causes: Magnetization from phones, speakers, or magnetic clasps; impact damage to the balance wheel; or contamination inside the movement.

Immediate Action: Test for magnetization using a compass—if the needle deflects when brought near the watch, demagnetization will likely restore accuracy. For impact-related issues, professional assessment is necessary.

Winding and Crown Operation Problems

Increased Winding Resistance

Some NH35 watches develop increased resistance when hand-winding, particularly those with screw-down crowns.

Common Causes: Dried lubricants in the winding mechanism, worn crown seals creating friction, or debris in the crown tube affecting smooth operation.

Solutions: Often resolved during regular service when winding components are cleaned and lubricated. Immediate relief may be possible by ensuring the crown is fully unscrewed before winding and using gentle, consistent motion rather than rapid or forceful winding.

Crown Slipping or Poor Engagement

Difficulty engaging positions or crown slipping during operation suggests mechanical wear or adjustment needs.

Diagnosis: Test crown positions systematically—time setting should provide clear resistance difference from winding position. Date setting should engage positively without slipping.

Professional Attention Required: Crown mechanism issues typically require watchmaker attention, as improper adjustment can damage delicate setting wheels and compromise water resistance.

Automatic Winding Concerns

Insufficient Power Reserve Despite Activity

Some users notice their NH35 stops running despite regular wear, suggesting automatic winding inefficiency.

Contributing Factors: Sedentary lifestyle providing insufficient wrist motion, rotor mechanism contamination reducing efficiency, or mainspring issues affecting power storage.

Solutions: Try more vigorous manual winding to test mainspring capacity. If manual winding provides normal power reserve but automatic winding fails, the rotor mechanism likely needs service. Office workers often benefit from occasional manual winding to supplement limited wrist motion.

Rotor Noise Development

While some rotor noise is normal in the NH35, excessive or grinding sounds indicate developing problems.

Normal Noise: Gentle swooshing or light clicking during sudden movements is typical and not concerning.

Concerning Sounds: Grinding, scraping, or loud rattling suggests rotor bearing wear, loose rotor components, or contamination. These issues require professional attention to prevent damage to surrounding components.

Date Mechanism Problems

Date Change Timing Issues

The NH35’s date should change sharply around midnight, but some watches develop slow or partial date changes.

Mechanical Causes: Worn date change components, insufficient mainspring power reaching the date mechanism, or incorrect hand position affecting timing.

User Error Prevention: Never adjust the date between 9 PM and 3 AM when the change mechanism is partially engaged. Always advance time past midnight to complete any partial date change before setting the date manually.

Professional Solutions: Date mechanism problems typically require disassembly to access and adjust the change components, making professional service necessary for reliable repair.

Power Reserve and Stopping Issues

Shorter Than Expected Power Reserve

NH35 watches should run approximately 41 hours when fully wound and stationary, with longer duration during normal wear.

Diagnostic Steps: Fully wind manually and time the duration until stopping. If significantly under 35 hours, service is likely needed. If normal when fully wound but stopping during wear, automatic winding efficiency may be compromised.

Contributing Factors: Aged lubricants increasing friction, worn mainspring reducing capacity, or rotor mechanism problems preventing adequate winding during wear.

Environmental and Usage Considerations

Temperature Sensitivity

Some NH35 watches show increased accuracy variation in extreme temperatures, running fast in heat or slow in cold.

Normal Variation: Minor temperature effects (5-10 seconds per day) are normal for mechanical movements and don’t indicate problems.

Excessive Sensitivity: Major temperature effects suggest regulation issues or lubricant problems that professional service can address.

Humidity and Moisture Concerns

While the NH35 itself is not water-resistant, moisture penetration can cause several problems.

Early Warning Signs: Fogging inside the crystal, particularly during temperature changes, indicates compromised water resistance requiring immediate attention.

Prevention: Ensure crown proper sealing, avoid temperature extremes after water exposure, and have gaskets tested regularly during service.

When to Seek Professional Service

Immediate Service Indicators:

- Sudden accuracy shifts exceeding ±30 seconds per day

- Grinding or unusual noises during operation

- Crown operation difficulties or loose feel

- Visible moisture inside the crystal

- Stopping despite adequate winding

Routine Service Timing:

- Gradual accuracy drift over months

- Increased winding resistance

- Approaching 3-5 year service interval

- After any significant impact or shock

Understanding these common issues and appropriate responses helps NH35 owners maintain their watches properly while recognizing when professional intervention provides the best long-term value for their investment.